PROVIDING QUALITY LASER CUTTING & CNC BENDING SERVICES

AT AFFORDABLE PRICES

LASER CUTTING machines are used to cut sheet-form materials by the use of a high-powered laser beam. The material melted by the laser beam is then blown away by a high pressure assist gas, leaving an edge with a smooth finishing.

Laser cutting machines can be used to process many materials, the more common ones include mild steel, stainless steel, aluminium, brass, plastics and wood.

Compared to other cutting methods, laser cutting is able to strike a good balance between speed and precision. Laser cutting machines are able to achieve tighter tolerances than methods like shearing, plasma and water jet cutting. Though less precise than wire cutting, laser cutting is a much faster cutting method.

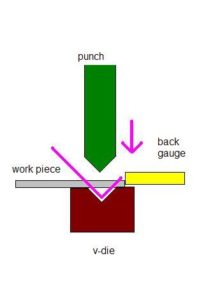

With the use of press brakes and the appropriate tooling, sheet metal can be plastically deformed and bent to the shape and angle desired. At Latech, we make use of air bending to process our parts for its greater cost economy and flexibility.

The work piece to be bent will be placed against the back gauge and in between the punch and the V-die. The press brake will then apply force and the workpiece will be pressed down against the V-die at its bottom by the punch at the top. The depth of movement can be controlled to attain the desired angle and V-dies of different angles will be needed for work pieces with desired angle below 90 degree.

Equipped computer numeric control (CNC), our press brakes are able to achieve better accuracy and repeatability.

Common items requiring this manufacturing method include brackets, trays, boxes etc.

Metal fabrication can be defined as the manipulation of metal material from one form to another. This usually involves the manufacturing of metal structures through processes comprising the cutting, bending and assembly of the raw material.

A simple example would be the construction of a custom stainless steel cabinet. The typical process can include these steps:

1. Laser cutting the panels

2. Band sawing tubes for the skeleton of the structures

3. Bending the panels

4. Welding of the panel, tubes and parts like hinges

5. Touching up the welding areas

LASER CUTTING

LASER CUTTING machines are used to cut sheet-form materials by the use of a high-powered laser beam. The material melted by the laser beam is then blown away by a high pressure assist gas, leaving an edge with a smooth finishing.

Laser cutting machines can be used to process many materials, the more common ones include mild steel, stainless steel, aluminium, brass, plastics and wood.

Compared to other cutting methods, laser cutting is able to strike a good balance between speed and precision. Laser cutting machines are able to achieve tighter tolerances than methods like shearing, plasma and water jet cutting. Though less precise than wire cutting, laser cutting is a much faster cutting method.

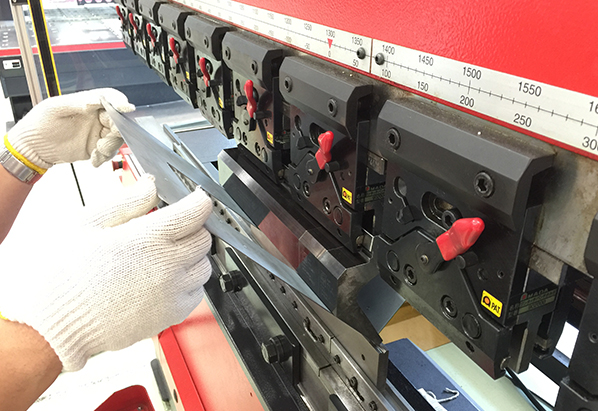

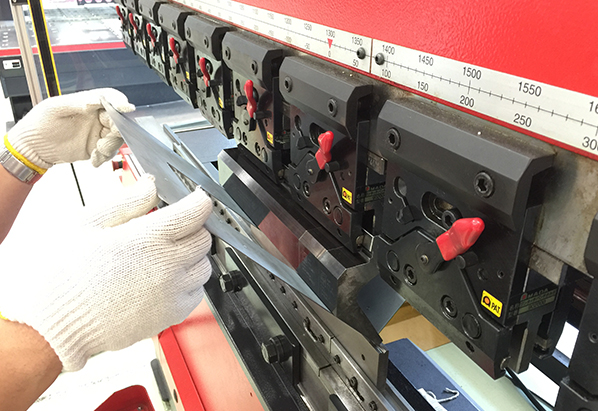

CNC BENDING

With the use of press brakes and the appropriate tooling, sheet metal can be plastically deformed and bent to the shape and angle desired. At Latech, we make use of air bending to process our parts for its greater cost economy and flexibility.

The work piece to be bent will be placed against the back gauge and in between the punch and the V-die. The press brake will then apply force and the workpiece will be pressed down against the V-die at its bottom by the punch at the top. The depth of movement can be controlled to attain the desired angle and V-dies of different angles will be needed for work pieces with desired angle below 90 degree.

Equipped computer numeric control (CNC), our press brakes are able to achieve better accuracy and repeatability.

Common items requiring this manufacturing method include brackets, trays, boxes etc.

FABRICATION

Metal fabrication can be defined as the manipulation of metal material from one form to another. This usually involves the manufacturing of metal structures through processes comprising the cutting, bending and assembly of the raw material.

A simple example would be the construction of a custom stainless steel cabinet. The typical process can include these steps:

1. Laser cutting the panels

2. Band sawing tubes for the skeleton of the structures

3. Bending the panels

4. Welding of the panel, tubes and parts like hinges

5. Touching up the welding areas

LOCATE US

CONTACT US & SET AN APPOINTMENT WITH US.

LET US SOLVE YOUR NEEDS

OUR OFFICE

BLOCK 5049

ANG MO KIO INDUSTRIAL PARK 2 #01-635

SINGAPORE 569552

EMAIL: LATECH@SINGNET.COM.SG

PHONE: 6484 5507

FAX:6484 5508

OPENING HOURS

Monday – Friday: 0800 – 1830

Saturday: 0800 – 1530

Sunday & PH: Closed

OUR OFFICE

BLOCK 5049

ANG MO KIO INDUSTRIAL PARK 2 #01-635

SINGAPORE 569552

EMAIL: LATECH@SINGNET.COM.SG

PHONE: 6484 5507

FAX:6484 5508

OPENING HOURS

Monday – Friday: 0800 – 1830

Saturday: 0800 – 1830

Sunday & PH: Closed